Working Principle of Pendulum Roller Grinding Mill

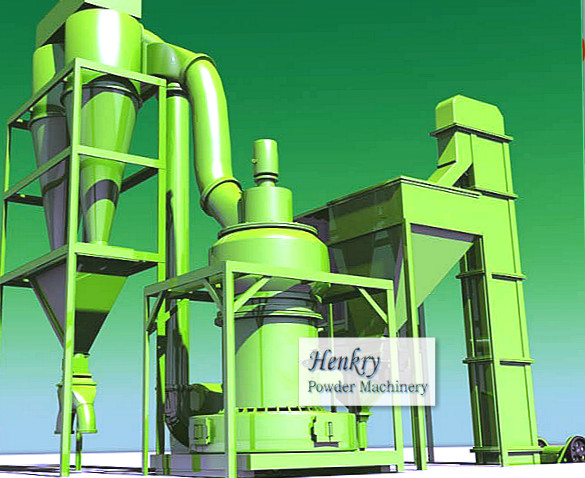

The pendulum roller grinding mill is mainly used to make 80-400 mesh powder, which has the following components: elevator, hopper, feeder, mill, classifier, reducer, blower, cyclone collector, pipes and etc. This kind of pendulum roller grinding mill is mainly used to grind any non-metal minerals with Moh’s hardness less than 6. The minerals includes the following: calcium carbonate, talc, calcite, dolomite, marble, gypsum, barite, clay, kaolin, quick lime and so on.

The crushed raw material (less than 20mm or 30mm or 40mm) will be conveyed into the elevator and then to the feeding hopper by the elevator. Belt conveyor under the hopper will move the crushed raw material into the pendulum roller grinding mill grinding house. Driven by the reducer and central shaft, the spider arm, roller assembly and shovels can rotate. In the grinding mill house, the roller on the roller assembly will also move centrifugally and the crushed raw material can be ground into powder between roller and ring.

The ground powder will go up through the classifier with help of high-pressure blower. And the coarse powder that cannot go through the classifier falls down to the grinding house, which will be reground between roller and ring. The qualified powder will be collected in the cyclone and in the pulse jet collector.

Improved Performance and Special Features of Pendulum Roller Grinding Mill

- Roller and Ring are made higher and the shovel is made larger to increase the grinding contact surface and grinding force to increase output.

- Improved Reducer: the newly-designed reducer rotation can be adjusted according to customer’s requirement to increase output.

- Improved Classifier: the turbine wheel use big blade to increase the fineness control, classifying precision and air volume passing area.

- Bigger size cyclone to increase collecting efficiency.

- High-pressure blower: air pressure can be increased to make air conveying capacity

How to Improve the Output of the pendulum roller grinding mill

The way to increase the efficiency of pendulum roller grinding mill is to lower the wearing rate and prolong working life. Firstly: we should feed material with less than 6 Moh’s hardness to protect the pendulum roller grinding mill. Secondly, feeding material size should also be controlled within a range (usually less than 20mm or 30mm); The feeding rate is also needed to be controlled at a even rate. Thirdly, the iron or steel cannot go into the grinding house with a help of electromagnetic iron eliminator. Fourthly, wearing parts are made of wear-resistant alloy material to increase its surface hardness and anti-resistant ability by heat treatment. Most of all, lubrication should be carried out regularly to protect all parts that need to be lubricated.

Technical Data of Pendulum Roller Grinding Mill:

grindingmill88@gmail.com

grindingmill88@gmail.com